新聞資訊

News以市場(chǎng)為導(dǎo)向,注重產(chǎn)品的創(chuàng)新研發(fā).

上海太白螺旋輸送機(jī)用于飲料瓶包裝線輸送案例

- 分類:企業(yè)新聞

- 發(fā)布時(shí)間:2016-08-29 17:48

【概要描述】 隨著包裝產(chǎn)業(yè)的迅猛發(fā)展,產(chǎn)品的包裝不再是以單機(jī)完成一道道工序、生產(chǎn)效率極低的作業(yè)過程了。取而代之的是可以降低人工成本、提升生產(chǎn)效率的包裝自動(dòng)化流水線。

包裝自動(dòng)化流水線將相互獨(dú)立的自動(dòng)或半自動(dòng)包裝設(shè)備,輔助設(shè)備等按包裝工藝的先后順序組合起來,使被包裝物品從流水線一端進(jìn)入,經(jīng)過不同的包裝設(shè)備,包裝材料在相應(yīng)的包裝工位加入,包裝成品從流水線的末端不斷輸出。通過整合,包裝自動(dòng)化流水線使得包裝設(shè)

上海太白螺旋輸送機(jī)用于飲料瓶包裝線輸送案例

【概要描述】 隨著包裝產(chǎn)業(yè)的迅猛發(fā)展,產(chǎn)品的包裝不再是以單機(jī)完成一道道工序、生產(chǎn)效率極低的作業(yè)過程了。取而代之的是可以降低人工成本、提升生產(chǎn)效率的包裝自動(dòng)化流水線。

包裝自動(dòng)化流水線將相互獨(dú)立的自動(dòng)或半自動(dòng)包裝設(shè)備,輔助設(shè)備等按包裝工藝的先后順序組合起來,使被包裝物品從流水線一端進(jìn)入,經(jīng)過不同的包裝設(shè)備,包裝材料在相應(yīng)的包裝工位加入,包裝成品從流水線的末端不斷輸出。通過整合,包裝自動(dòng)化流水線使得包裝設(shè)

- 分類:企業(yè)新聞

- 發(fā)布時(shí)間:2016-08-29 17:48

隨著包裝產(chǎn)業(yè)的迅猛發(fā)展,產(chǎn)品的包裝不再是以單機(jī)完成一道道工序、生產(chǎn)效率極低的作業(yè)過程了。取而代之的是可以降低人工成本、提升生產(chǎn)效率的包裝自動(dòng)化流水線。

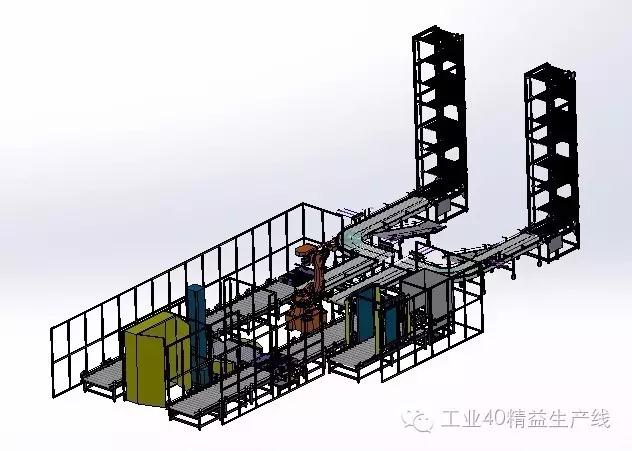

包裝自動(dòng)化流水線將相互獨(dú)立的自動(dòng)或半自動(dòng)包裝設(shè)備,輔助設(shè)備等按包裝工藝的先后順序組合起來,使被包裝物品從流水線一端進(jìn)入,經(jīng)過不同的包裝設(shè)備,包裝材料在相應(yīng)的包裝工位加入,包裝成品從流水線的末端不斷輸出。通過整合,包裝自動(dòng)化流水線使得包裝設(shè)備的組合起到了“一加一大于二”的作用,極大地改善了以前單機(jī)包裝流程復(fù)雜、不規(guī)范的局面。

應(yīng)勢(shì)而生——包裝自動(dòng)化流水線

由于現(xiàn)代化生活節(jié)奏加快,消費(fèi)者對(duì)休閑食品、快速消費(fèi)食品的需求量越來越大。未來,食品包裝機(jī)械行業(yè)對(duì)包裝設(shè)備智能化、自動(dòng)化的需求也會(huì)越來越多。隨著行業(yè)競(jìng)爭(zhēng)加劇,采購、生產(chǎn)成本的提高。食品加工包裝企業(yè)希望尋找一款集封箱、噴碼、打包、碼垛等包裝環(huán)節(jié)于一體的自動(dòng)化設(shè)備,以減少生產(chǎn)成本,提高運(yùn)營效率。

優(yōu)化組合,創(chuàng)出新意,創(chuàng)出效率。紙箱自動(dòng)化包裝生產(chǎn)線集開箱、裝箱、封箱、貼標(biāo)、噴碼、打包、碼垛、纏繞為一體,并利用先進(jìn)技術(shù),使整個(gè)生產(chǎn)流程簡(jiǎn)單、準(zhǔn)確、安全、迅速,該包裝流水線已達(dá)到國內(nèi)的先進(jìn)水平。

現(xiàn)在客戶的需求不斷上升,不僅對(duì)產(chǎn)品的質(zhì)量、性能等提出了更嚴(yán)格的要求,連包裝劑量的精準(zhǔn)性,包裝外觀的美觀性等方面也有更多個(gè)性化的需求,因此帶來了包裝機(jī)械行業(yè)的快速發(fā)展,各類型的包裝機(jī)械層出不窮。

目前,國外的包裝工業(yè)正在向全部自動(dòng)化發(fā)展。自動(dòng)包裝機(jī)械與自動(dòng)包裝流水線的大量采用,可以實(shí)現(xiàn)高效率低費(fèi)用的要求。作為發(fā)展最為迅速的經(jīng)濟(jì)實(shí)體,我國正在成長為世界的制造和包裝中心,各類自動(dòng)化包裝生產(chǎn)線的需求將進(jìn)一步提升。

有關(guān)專家指出,和國外包裝線生產(chǎn)企業(yè)相比,國內(nèi)廠家的生產(chǎn)線配套性能一致性、設(shè)備穩(wěn)定性、使用壽命等方面還具有一定的差距。為了適應(yīng)國內(nèi)迅猛增長的包裝需求,有關(guān)企業(yè)必須加大專業(yè)化包裝線的技術(shù)研究和產(chǎn)品革新,更好的把握國內(nèi)市場(chǎng)的發(fā)展機(jī)遇。

隨著科學(xué)技術(shù)的不斷發(fā)展進(jìn)步,生產(chǎn)領(lǐng)域推陳出新對(duì)包裝技術(shù)和包裝設(shè)備提出的新要求,包裝機(jī)械競(jìng)爭(zhēng)日趨激烈,自動(dòng)化的包裝生產(chǎn)線優(yōu)勢(shì)將逐漸突出,從而促進(jìn)包裝機(jī)械行業(yè)整體發(fā)展

With the rapid development of the packaging industry, the packaging of products is no longer a single process to complete a series of processes, production efficiency is extremely low. Instead, it is a packaging automation pipeline that reduces labor costs and increases productivity.

The packaging automation line combines independent automatic or semi-automatic packaging equipment and auxiliary equipment according to the order of the packaging process, so that the packaged articles enter from the end of the assembly line. After different packaging equipment, the packaging materials are added at the corresponding packaging station. The finished package is continuously output from the end of the line. Through integration, the packaging automation line makes the combination of packaging equipment play the role of “one plus one is greater than two”, which greatly improves the complicated and irregular situation of the previous single machine packaging process.

Come to the forefront - packaging automation line

Due to the accelerated pace of modern life, consumers are increasingly demanding snack foods and fast-food consumption. In the future, the food packaging machinery industry will have more and more demand for intelligent and automated packaging equipment. As industry competition intensifies, procurement and production costs increase. Food processing and packaging enterprises hope to find an automation equipment that integrates sealing, sealing, packaging, palletizing and other packaging links to reduce production costs and improve operational efficiency.

Optimize the combination, create new ideas and create efficiency. The carton automatic packaging production line integrates unpacking, packing, sealing, labeling, coding, packing, palletizing and winding, and utilizes advanced technology to make the whole production process simple, accurate, safe and rapid. The packaging line has been Reach the advanced level in the country.

Nowadays, the demand of customers is constantly rising, not only the stricter requirements on the quality and performance of the products, but also the accuracy of the packaging dose, the aesthetic appearance of the packaging, etc., and more personalized demands, thus bringing packaging machinery. With the rapid development of the industry, various types of packaging machinery emerge one after another.

At present, the foreign packaging industry is developing towards full automation. The large number of automatic packaging machines and automatic packaging lines can achieve high efficiency and low cost. As the fastest-growing economic entity, China is growing into a manufacturing and packaging center in the world, and the demand for various automated packaging production lines will be further enhanced.

Relevant experts pointed out that compared with foreign packaging line manufacturers, domestic manufacturers have a certain gap in the performance consistency, equipment stability and service life of the production line. In order to meet the rapidly growing domestic packaging demand, relevant enterprises must increase the technical research and product innovation of specialized packaging lines to better grasp the development opportunities in the domestic market.

With the continuous development and advancement of science and technology, the production field has introduced new requirements for packaging technology and packaging equipment. The competition for packaging machinery is becoming increasingly fierce, and the advantages of automated packaging production lines will gradually become prominent, thus promoting the overall development of the packaging machinery industry.